The bridge constructions must be done with utmost precision using the right components and parts. The bridges generally consist of two parts which are a substructure and a superstructure. The superstructure of the bridge has to face various dimensional deformations due to the type of pressure and load put on it. The deformations can include.

- Bridge deformation under tremendous load

- Wind loads

- Thermal expansion

- Creep and concrete shrinkage

- Seismic force

- Longitudinal force

- Settlement of supports

All this pressure and load can take a toll on the bridge. When the construction isn’t done properly, there can be bridge failure which can cause damage to property and life. Thus, it is essential to have a device placed between the substructure and the superstructure, which helps with adequate movements without damage to the bridge. The structures will help provide stability and adequate capacity to the bridge for facing the loads daily. For such cases, the most popular device is the bridge bearings, which offers great functionality to the bridge by allowing translational and rotational movements offering help support the vertical loads. It is the PTFE bridge bearings that are preferable options as they provide a vital interface between substructure and superstructure.

PTFE structural bearings

The use of PTFE in the manufacturing of bridge bearings has increased tremendously over the years. Although the application of PTFE bridge bearings isn’t possible in all structural bridge construction, they are still a highly preferred option.

The PTFE bridge bearings come with an extremely low coefficient of friction and self-lubricating characteristics, which makes them resistant to the chemicals. Also, it offers them the ability to operate well even during high temperatures.

On one side, an unmodified PTFE can be efficiently used for a PV value of 1,000. On the other side, a glass fiber, granite, or other inserted material PTFE can be efficiently used for PV values of 10,000 or more. This thus shows the PTFE bridge bearings can be used with PV valves at low speeds, which has coefficient friction as low as 0.05 to 0.1.

The low PTFE coefficient of friction is because of two primary reasons.

- The PTFE values against a stainless steel exhibit a lower coefficient of friction than when PTFE is used against a solid structure. Numerous studies have revealed the coefficient of PTFE between any two solid materials is the lowest.

- The coefficient of PTFE bridge bearings greatly reduces with an increase in the pressure.

Types of PTFE

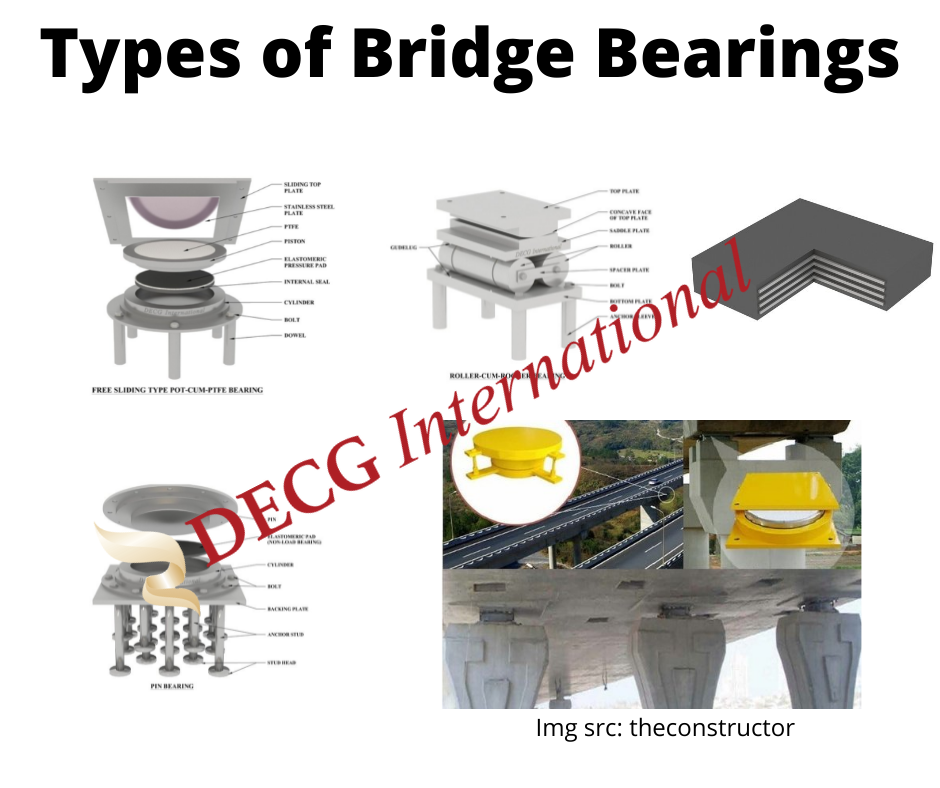

The PTFE is generally used in two types of structural bearings, which include.

A PTFE slide bearing is a system of two plates wherein one plate slides over the other. This type of bearing allows for better longitudinal and transverse translation unless they are specifically restrained in any direction. But remember, no rotation is possible unless they are specifically provided in articulation form. Also, the bearing restricts the vertical loads.

The PTFE slide bearings are generally used in instances where the span is less than 30m as the moving capacity of the bearings is generally small. The bearing is made up of two sheets which are generally preferred to be high-density carbon steel. In between the sheets, there is a layer of PTFE and polished stainless steel. The stainless steel section is attached to the bearing plate while the other section PTFE is attached to the other plate. Finally, a recess is created for providing better bonding on the bearing plate to which the PTFE is attached.

The regular maintenance of the PTFE slide bearings is essential to ensure proper friction, or else the horizontal transmission force to the substructure will increase greatly. This is why the frequency lubrication of the bearing has been prescribed to be three years.

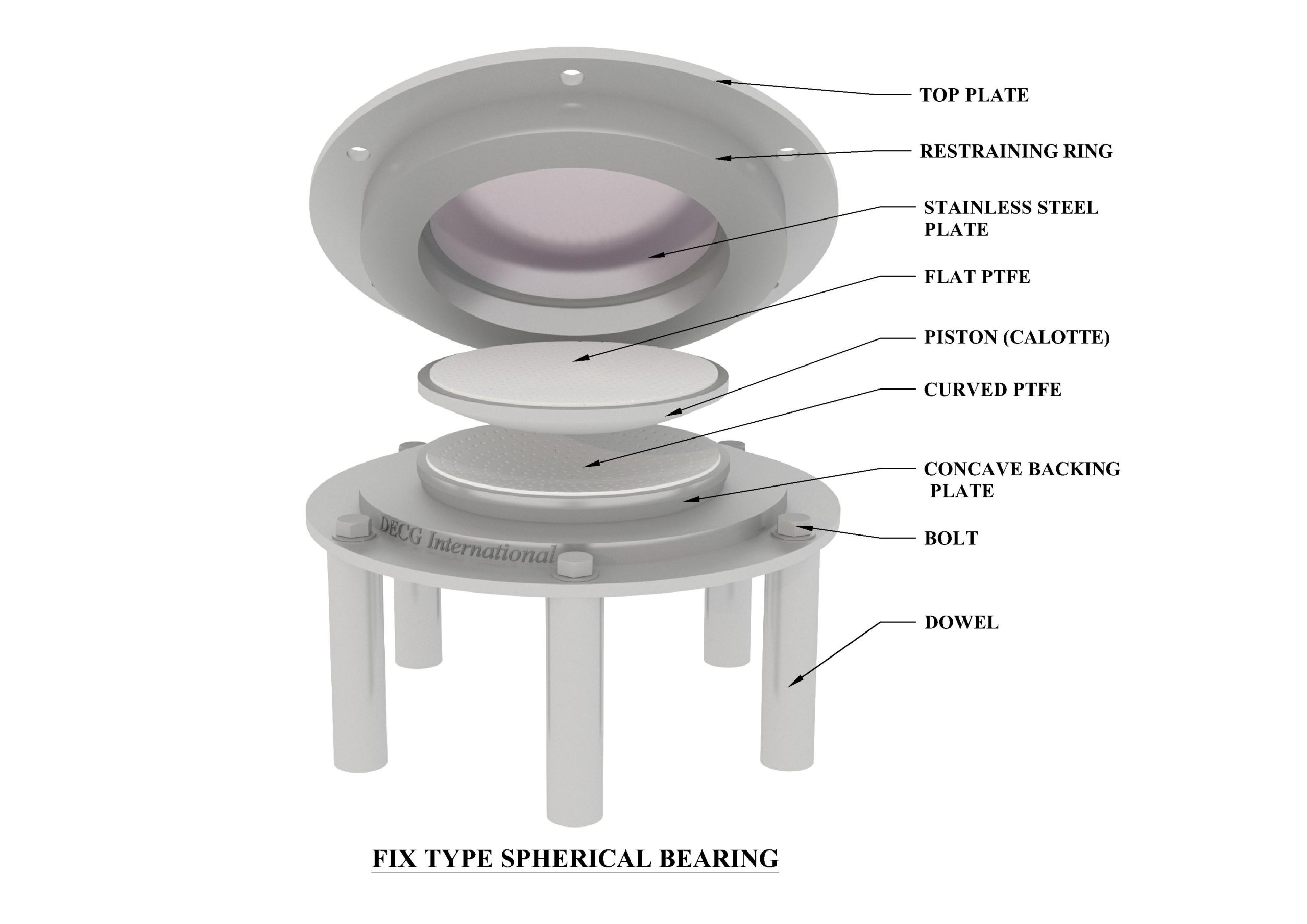

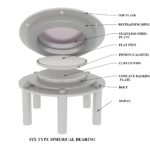

This bearing consists of a circular non reinforced rubber pad that is entirely sealed inside the steel. The rubber present inside the bearing is prevented from any bulging with the pot walls, similar to a fluid present under high pressure. During the earlier times, the bearings were manufactured without PTFE. However, it was the requirement for horizontal movement besides the load-bearing capacity which made this a necessity. With the increasing demand for PTFE bridge bearings, you can easily find Pot PTFE bridge bearing manufacturers in India who can offer you high-quality bearings at a fair rate.

The Pot PTFE bearings are preferred due to the high degree of rotation they provide to the bridges. The Pot PTFE bearings are difficult to manufacture due to the amount of recess required for the pot and the ceiling elements for properly storing the elastomer within the pot. This is why the ceilings are preferred to be metallic. Besides this, the PTFE plate must be placed well into the piston and provided with adequate dimples for additional lubricants during the time of installation.

Standard working conditions for Pot PTFE bearings

- A temperature range between -10° Celsius to 50° Celsius

- A pot bearing of 1500 mm with scope for specification

- Rotation up to 0.025 radians

- Avoid standing pressure in excess of 40MPa bearing, based on the type of filler used.

PTFE structure bearing design

There are numerous design codes for structural bearings. But almost all prescribe the use of similar materials and have similar requirements about the strength and grade of the material. But in India, the Pot PTFE bearing is ORC:83, while for the sliding once there is no established system yet. Ultimately, the Pot PTFE bearing manufacturers in India must take the responsibility of designing bearing based on the customer requirement.

Contact the best PTFE bearing manufacturer.

There are numerous PTFE manufacturers in India, but to get the best, you can rely on DECG International for your bearings. We can offer you high-grade bearings that can fit well all your requirement. We can offer you fare priced products that can fit your requirements well and deliver you 100% satisfactory results. So, wait not and contact us today to make purchases of the highest quality bridge bearings in India.

Place order/enquiry

Recent Comments