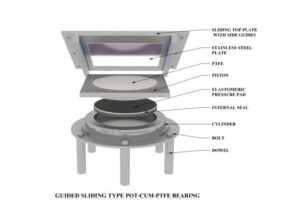

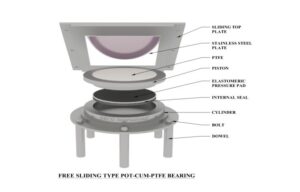

Pot PTFE bearing consists of a metal piston supported by a disc of unreinforced elastomer that is confined within a metal cylinder for allowing rotational movement about an axis in the horizontal plane and to bear and to bear and transmit vertical load. Pot bearings may be provided with sliding assembly (with or without restraint in the form of a guide along the desired direction to bear and transmit horizontal force) comprising of stainless steel plate attached to metal backing plate sliding in a horizontal plane over sliding material confined in recess(s) on the piston which shall be termed as sliding/Guided Pot bearings. Depending on the desired degree of freedom Pot bearings may be of three types as follows:

Types of POT PTFE Bearings

- Fixed Pot Bearings

Fixed Pot Bearings are fixed in all directions i.e. it is a type of bearing which along with vertical load, bears and transmits horizontal force in any direction and allows rotation about any axis in the horizontal plane without permitting any movement in the horizontal plane.

- Guided Sliding Pot Bearings

It is a type of POT bearing which along with the vertical load bears and transmits horizontal force in one direction only and allows movement perpendicular to that direction and allows rotation about any axis in a horizontal plane.

- Free Sliding Pot Bearings

It is a type of POT bearing which bears and transmits vertical load and allows movement in any direction in the horizontal plane and accommodates rotation about any axis in a horizontal plane.

Benefits of POT PTFE Bearing

- POT PTFE Bearings are used when bearing movements are large and need long-term serviceability. These offer a longer working life and small size as compared to elastomeric bearings.

- They are multi rotational and have negligible vertical deflection under load.

- They have high vertical and horizontal load capacity.

- They have resistivity against outer atmospheric corrections.

- POT bearings are preferred when the bearing rotations are large, thus providing long time serviceability.

- These bearings offer an extended service life when they are compared to elastomeric bearings.

- They are smaller in size than the other elastomeric bearings.

- They have a longer maintenance time i.e. they can be used sufficiently for a long period of time without repair or maintenance.

Application

Pot bearings are very useful where a high load is under consideration. These bearings are suited for curved or skewed bridges where the direction of the rotation varies or is uncertain.

Installation of Pot PTFE Bearings

- The components of the Pot PTFE bearings are checked and then placed into the box for installation.

- The PTFE plate and stainless steel plate should be well protected from any scratching.

- The supporting padding stone is set under the pot bearing and the concrete. The height of the padding stone is an important part of the installation, maintenance, and replacement of the pot bearing.

- The supporting padding stones and concrete pier top should be equipped with reinforced mesh according to the JTG D62-2004.

- The central line of the pot bearing is in alignment and parallel to the main beam.