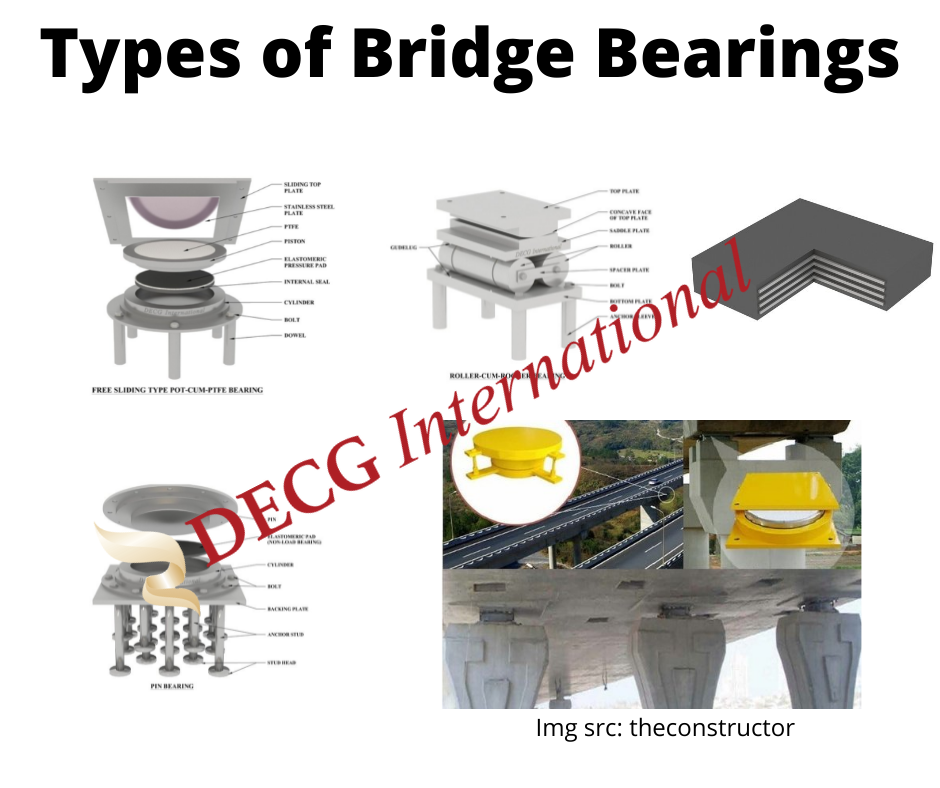

Bridge bearings are structure equipment or devices that are installed between bridge substructures or superstructures. The bearings are used to transfer the applied load on the bridge, including earthquake load, wind load, traffic load, etc. Bridge bearings are also responsible for the relative movements between the superstructure and substructure. For example, rotation and translational movements in horizontal or transverse directions.

Bearings used in constructing bridges are divided into two major categories – expansion bearing and fixed bearing. While the expansion bearings can permit translational and rotational movements, the latter only allows rotational and some translational movements. DECG International is one of India’s best bridge bearing manufacturers that offer all the various types of bridge bearings and also guarantee high quality.

Types of Bridge Bearing

The different types of bridge bearings and their uses in various constructional areas are as follows:

Pot Bearings:

A bearing consisting of a metal piston supported by a disc of unreinforced elastomer that is confined within a metal cylinder for allowing rotational movement about any axis in horizontal plane and to bear and transmit vertical load. Pot bearings may be provided with sliding assembly (with or without restraint in the form of guide along a desired direction to bear and

transmit horizontal force) comprising of stainless steel plate attached to metal backing plate sliding in horizontal plane over sliding material confined in recess(s) on the piston which shall be termed as Sliding / Guided Pot bearings. Depending on the desired degree of freedom Pot bearings may be of three types as follows:

- Fixed Pot Bearing

- Sliding Pot Bearing

- Guided Pot Bearing

Rocker and Pin Bearings

Rocker is an expansion bridge bearing that is composed of a curved surface at the bottom that can accommodate the translational movement and a pin on the top that facilitates the rotational movement of the bridge structures.

Rocker and Pin bridge bearings are used in steel bridge structures and are considered when the bridge movement is known and described adequately. These bridge bearings can undergo severe corrosion and deterioration, making regular inspections and maintenance an essential part of the construction.

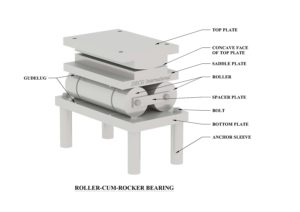

Roller Bearings

Roller bearings are used to construct concrete or steel bridge structures. The roller bearing can be used in two different forms, namely – single roller and multiple roller bearings. Multiple roller bearings have several rollers installed under the two plates and can facilitate both rotational and translational motion for the bridge. One of the best things about roller bearings is that they are cheap to manufacture, but they have a limited weight capacity, making them suitable for specific constructions. On the other hand, multiple roller bearings are expensive and can short large vertical loads. These rollers need regular inspections and rehabilitation since they are susceptible to corrosion and damages.

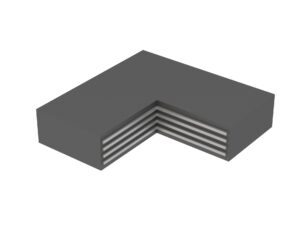

Elastomeric bearings

Elastomeric bearings are elastomers manufactured from synthetic and natural rubber. These bridge bearings support both translational and rotational movements through elastomer deformation. Elastomeric bearings can carry large loads and prevent lateral bulging of the elastomers.

The number of elastomer pads needed for the construction depends on the type of reinforcement used for the bridge. For instance, steel reinforces elastomeric bearings are the strongest, and plain elastomeric pads are the weakest. One of the best things about Elastomeric bridge bearings is that they are neither expensive nor require any maintenance after installation.

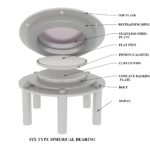

Spherical Bearings:

The Spherical bearings consists of a pair of matching concave and convex steel spherical backing plates with a low friction sliding interface in between them permitting the rotation by in-curve sliding. For the purpose of providing the translation

Ability, bearings are combined with the flat sliding elements. Depending on the desired degree of freedom Spherical bearings may be of three types as follows:

- Fixed Spherical Bearing

- Sliding Spherical Bearing

- Guided Spherical Bearing

Wrapping Up!

DECG International is one of the best bridge bearing manufacturers in India. We ensure the proper manufacturing of the highest quality bridge bearings for all construction needs. We have an excellent infrastructure that helps us provide the best quality construction products to all our clients.

Reference Sources:

Recent Comments