The bearings for decades have been used in the bridges to offer adequate support for the movement. Today the countries globally have started investing their resources and money to improve their transportation system and accommodate the needs of daily vehicles. But to face the daily weight of such a tremendous amount of vehicles, the bridges require proper construction and support. This is where the electromagnetic during are used to prevent any bridge failure.

Natural disasters are a common cause resulting in shifting bridge sections, bridge failures, collapsing decks, etc., which puts a great threat to the property and human life. To avoid such issues, the bridges are designed for moderate movement. A bridge must be capable of facing heavy traffic, natural disaster, temperature change, high wind speeds, etc. Thus, this makes the bridge bearings a crucial part of the structure. Here is a detailed guide that will offer you the right insights about elastomeric bearing usage in the bridge.

Elastomeric bridge bearings are popular for flexible structures

The elastomeric bearings are highly used for the construction of bridges as they offer great flexibility. The bearings are generally made up of materials like heavy-duty industrial standard rubber or neoprene. They are placed between the substructure and superstructure as a bridge beam or support to help distribute the load of the superstructure evenly. The superstructure moves in a desired manner during unexpected environmental conditions. Thus, the use of elastomeric bearing pads in bridges helps eliminate the risk of stress, leading to collapse.

Besides collapsing, the elastomeric bridge bearings also help boost the life of the bridges as it reduces the stress and wears and tear on the bridge materials and components. Further, the elastomeric bridge bearings help generate great savings for the government as they need not have to worry about replacing the components year after year.

3D simulation of elastomeric bearings are now widely used

Elastomeric bearings are a wide choice in terms of bearing as they are cost-effective and safe for usage. However, the components require professional testing and prototyping for usage in the bridge production. This is why the infrastructure and construction companies are using 3D simulation software to improve the testing process. Bridge bearings can be made of elastomeric materials that help stimulate and provide insights about factors like compression with rotation and shearing.

Such testing helps with observing the effects and relation of various bridge components with each other, which is greatly important for understanding the load-carrying capacity of a bridge.

The production of elastomeric bearings with cutting-edge technology will play a great role in bridge safety, longevity, and dependability.

Importance of testing on elastomeric bridge bearings performance

To enhance and improve the overall performance and reliability of elastomeric bearings, the manufacturers are now performing extensive testing to ensure the bearings comply with the local regulations. As per the reports, testing has shown the use of elastomeric bearings to greatly increase stress-handling capability. The report showed that the bridge failures occurred only when the bridge’s load-carrying capacity was increased 26 times more than the allowed limit. Thus, this shows elastomeric bearings offer greater reliability in terms of vertical performance.

When talking about shearing, elastomeric bearings are largely dependent on the fabrication conditions. As per the test, the bearings are at high risk of failure when the internal rubber layers were developed with a single rubber layer. Thus, the bearings must be used with complementing seismic devices, which will help increase the shear performance of the bearings. The practice of including multiple rubber parts has greatly increased the failure rate and is discouraged across the industry.

Customization in structural bearing assemblies

The bearings are used for different purposes. This is why elastomeric bridge bearing manufacturers have considered customizing molds to use neoprene and natural rubber to the best. The customizations are primarily classified into laminated, non reinforce, and sliding options. However, of all three, the reinforced elastomeric bridge bearings are widely used in instances where the stress like load and rotation are minimum and horizontal deflection. The cost of these bearings, when compared to the other, is relatively inexpensive.

The sliding elastomeric bridge bearings are highly used for bridge projects with a large magnitude of horizontal displacement. In such cases sliding elastomeric bearings is a cost-effective solution that helps add lower fractions sliding surface, enabling the unlimited horizontal displacement without any damage or impact on the bearing assembly structure height.

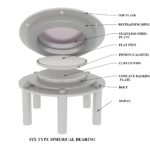

The two parts of sliding elastomeric bearing include the upper component made up of steel load plates integrated with the superstructure with a steel sheet. In contrast, the lower part of the structure is made up of low friction PTFE bridge bearing surface, integrated into a carbon base or steel sheet. The structure is then fixed to the elastomeric bearing, which finally is fixed to the load plate.

The laminated elastomeric bearings come with wear-resistant steel plates placed inside the structure, which greatly helps improve the vertical load-bearing abilities and horizontal deflection. It is efficiently handled by the bearing device. Here the steel plates are attached with the rubber vulcanization for generating alternating layers of elastomer. Thus, the laminated drawings offer great scope for customizations.

Contact a good Elastomeric bearing Manufacturer for quality purchase

Elastomeric bearings have shown great performance. The bridge bearing industry is consequently coming up with quantitative investigation for identifying and developing better solutions that play a self-adaptive role. With all the details, the importance of elastomeric bearings during bridge construction is clear. Thus, you must ensure to make the purchase of the bearing from a good manufacturer as this will guarantee better support and performance. You can rely on DECG International to make a purchase of fairly priced yet high-quality elastomeric bearings. Our company develops the best bearings which will fulfill the desired application. We use top-quality materials for manufacturing our products. No matter the type of bearing you want for the construction purpose, we have got it all to meet all your requirements at a fair rate.

Leave a Reply