Strip Seal Expansion Joint Manufacturers

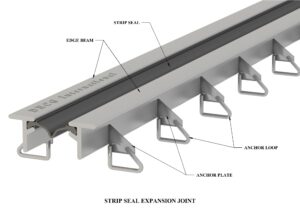

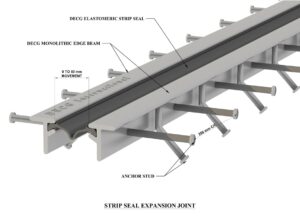

The Strip Seal Expansion Joint consists of a rubber gland, mechanically tightened between two steel edge members and provides a superior watertight proofing system. The design of the DECG Strip Seal System can easily accommodate

the high loads of vehicular traffic while effectively sealing joints in bridges and structures with very high movements up to 120mm it is to be noted that IRC recommend strip seal

joint for movement up to 80mm. Strip Seal Expansion Joints can be manufactured to accommodate a variety of field configurations along with multidirectional movements.

The DECG Strip Seal has been engineered so that the elastomeric Seal can be inserted either prior to or after the securing of the steel shapes to the superstructure. Machined Steel shapes maximize Seal install ability and minimizes manufacturing tolerance.

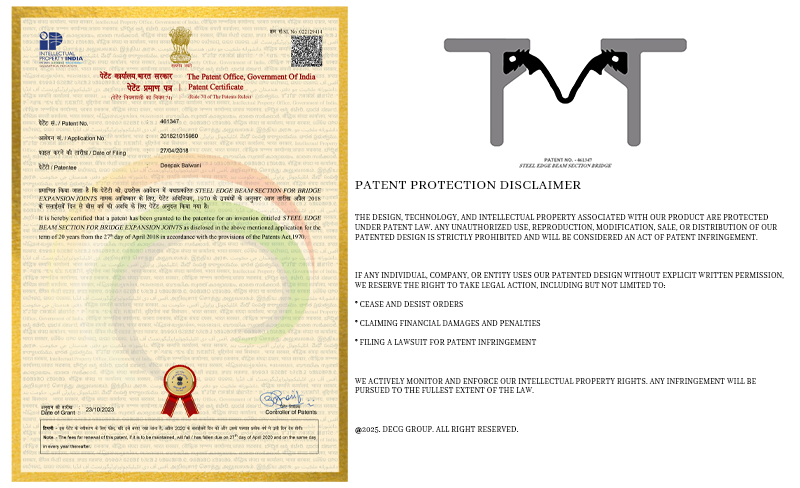

Strip Seal Expansion Joint system consists of an elastomeric gland mechanically locked between two steel edge members supplying a superior watertight sealing system. The rugged design of the Strip Seal Expansion Joint can easily accommodate the top loads of vehicular traffic while adequately sealing expansion joints in bridges and structures with movements. Machined Steel shapes maximize seal install ability and minimize manufacturing tolerance associated with overall Steel shape manufacture. MORT&H and RDSO Approved.

Features of Strip Seal Expansion Joints

- Strip seal expansion joints are retractable and solid on both directions parallel and perpendicular to the bridge axis to ensure vehicles runs freely and no noise.

- Strip seal expansion joints can prevent bridge from rainwater permeation and dirt clogging.

- Strip seal expansion joints are smooth and easy to install, check, maintain and clean.

- High power, can withstand the weight of vehicles and pedestrians.

Functions of Strip Seal Expansion Joint:-

- Allow the expansion/contraction of the span to which it is fixed without causing any suffering or vibration to the structure.

- They cause no trouble or hazard to the road user and offer good riding comfort.

- Should be efficient of with standing the traffic loads including dynamic effects.

- Surface reveal to traffic should be skid free and resistant to polishing.

- Make sure accessibility for inspections and easy maintenance with all parts vulnerable to wear being easily replaceable.

Application

- Strip seal joints are suitable for all kinds of bridges which are curved, slope, skew and wide. They can also work well on both new-built bridges and bridges have been built, both asphalt and concrete bridge surface. It also can be used in the highway and expressway.

- Having a bounded depth of the structure and being able to be installed speedily, strip seal expansion are extremely well-positioned to replace the damaged one in a restoration project.

Components Of Strip Seal Expansion Joint

Connecting With Splice Plate

Installation of Neoprene seal

- The elastomeric sealing element must be field installed.

- For strip seal and modular strip seal joints the sealing element should be in continuous lengths spanning the entire roadway width, and should not contain joints.

- Proper fit of the seal of the sealing element must be ensured.

- The seal shall be installed without any damage to the seal by suitable hand method or machine tools.(The tool should not have sharp edges.)

Installing Elastomeric Seal

Installing Elastomeric Seal

Don’t join the strip seal

Final Installation of Strip Seal Expansion Joint

Recent Comments